The Effect Of Additional Compressive Stress On The Seal Of Bottle Valve To Reduce The Leakage Rates Of Lpg Supply System

Abstract

The leak of LPG system can not be avoided in its uses as domestic fuel which considering it is one of the result from difussion fl ow. The leak because of difusion fl ow in 3 kg LPG tube is mostly caused by Laminar difussion fl ow known by comparing compressive stress with gasket seating stress which value less than 1 with characteristic in exponensial equations. Augmentation of compresive stress is proved in minimizing diffussion fl ow which cause subtraction in leak until 33.18% for NBR seal and 36.43% for vulcanized seal. Minimizing leak caused by increasing compressive stress is very affected by seal material composed representated by AL and nL. Numerical analysis founded that von mises stress received by seal is still under yield strength from rubber material with Factor of Safety (FOS) achieve at 7.08, this condition affi rms that defl ectation happened in Seal in its elastic area with maximum value about 1.326 mm. Beside that, numerical analysis show that difussion fl ow is occurred in seal creating gradation concetration based on the imminent of diffusion contact.

Keywords

Full Text:

PDFReferences

Esdm (2011, Februari 01). Artikel. Januari 2,

http://www.esdm.go.id/berita/artikel/56-

artikel/4122

Gu, B. et al. (2007) ‘Prediction of Leakage Rate

Through Sealing Connections with Non Metallic Gaskets’,

J.Chem. Eng., Vol. 15, No. 6, pp.837-841.

Gu, B.Q., Lu, X.F., “Test machine for gasket

performancesat elevated temperature and method for

leak detection”,China Petroleum Machinery, 27 (1),

- 41,46 (1999).

I Made Kartika Dhiputra, Raka CP, I Nym

Guni R. “An Experimental Study of Leakage Rate

Through Rubber-Seal of LPG Bottle Valve Used in

Household Gas Stove Burner”, ICE SEAM 2011,

Solo-Indonesia, October 3-4,2011

Serope Kalpakjian and Steven R. Schmid.

Manufacturing Engineering and Technology, 4th ed.,

Prentice-Hall Int., New Jersey, 2001.

Robert H. Wagoner and Jean-Loup Chenot.

Fundamentals of Metal Forming, John Wiley and

Sons Inc., New York, 1996.

Birk, A.M., The BLEVE: An Update and

Reexaminiation of Response Strategies, www.

springerlink.com

Kusumaputra, R Adhi (2009, Oktober 6). Listrik

dan Kompor, Penyebab Kebakaran Utama Rumah

Tangga. Desember 29,2011. http://properti.kompas.

com/read/2009/10/06/18401431.

Septiadevana, Riski. Komposisi Penyusun Minyak

Bumi dan Gas Alam. Desember 30,2011. http://kimia.

upi.edu/utama/bahanajar/kuliah_web/2008/Riski%20

Septiadevana%200606249_IE6.0/halaman_9.html.

Satria, Arief (2008). Perspektif Baru Pembangunan

untuk Menanggulangi Krisis Pangan dan Energi.

Desember 30 2011.Institute Pertanian Bogor. http://

rks.ipb.ac.id

Bab II Landasan Teori. (n.d). Desember 30,2011.

http://repository.upi.edu

Badan Standardisasi Nasional (2007). SNI

:2007 Tabung Baja. Jakarta.

Badan Standardisasi Nasional (2008). SNI

:2008 Regulator Tekanan Rendah. Jakarta.

Badan Standardisasi Nasional (2010). SNI

:2010 Karet Perapat Tabung. Jakarta.

Badan Standardisasi Nasional (2008). SNI

:2008 Katup Tabung. Jakarta.

Huebner, Kenneth H dan Earl A. Thornton. 1982.

The Finite Element Method for Engineer. Norfolk

Virginia : John Wiley & Sons, Inc

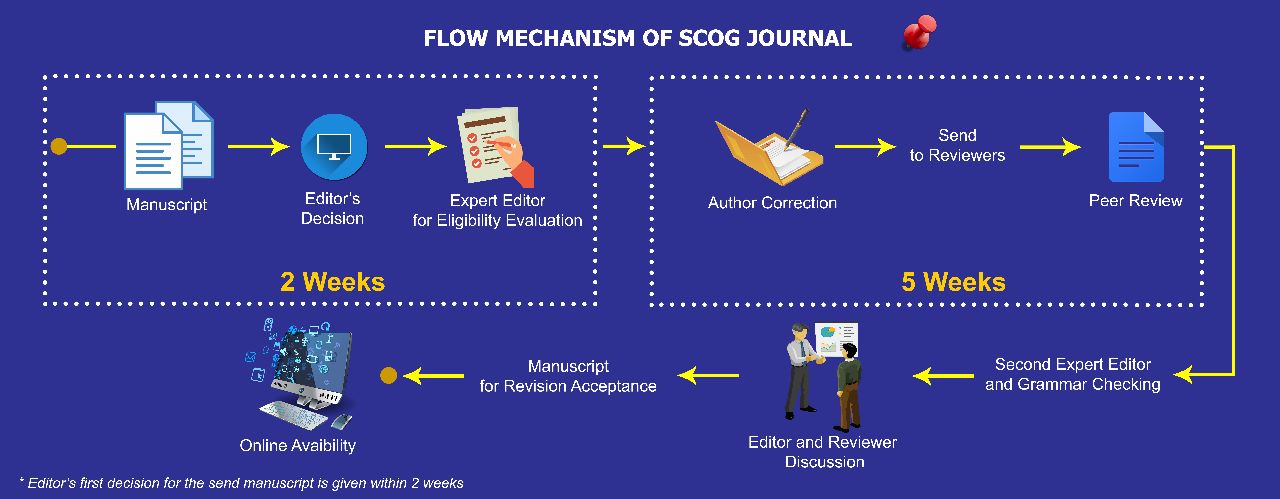

DOI: https://doi.org/10.29017/SCOG.35.3.785

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.