Utilization of Crude Oil as an Alternative Oil Base Mud Drilling Operation by “VICOIL†Standard Drilling Simulation Rig in MGTM Well UPN “Veteran†Yogyakarta Education Park Mineral Geotechnology Museum Field

DOI:

https://doi.org/10.29017/SCOG.44.2.588Keywords:

Swelling, Minerals, Crude Coconut Oil, Oil Base Mud, Rate of PenetrationAbstract

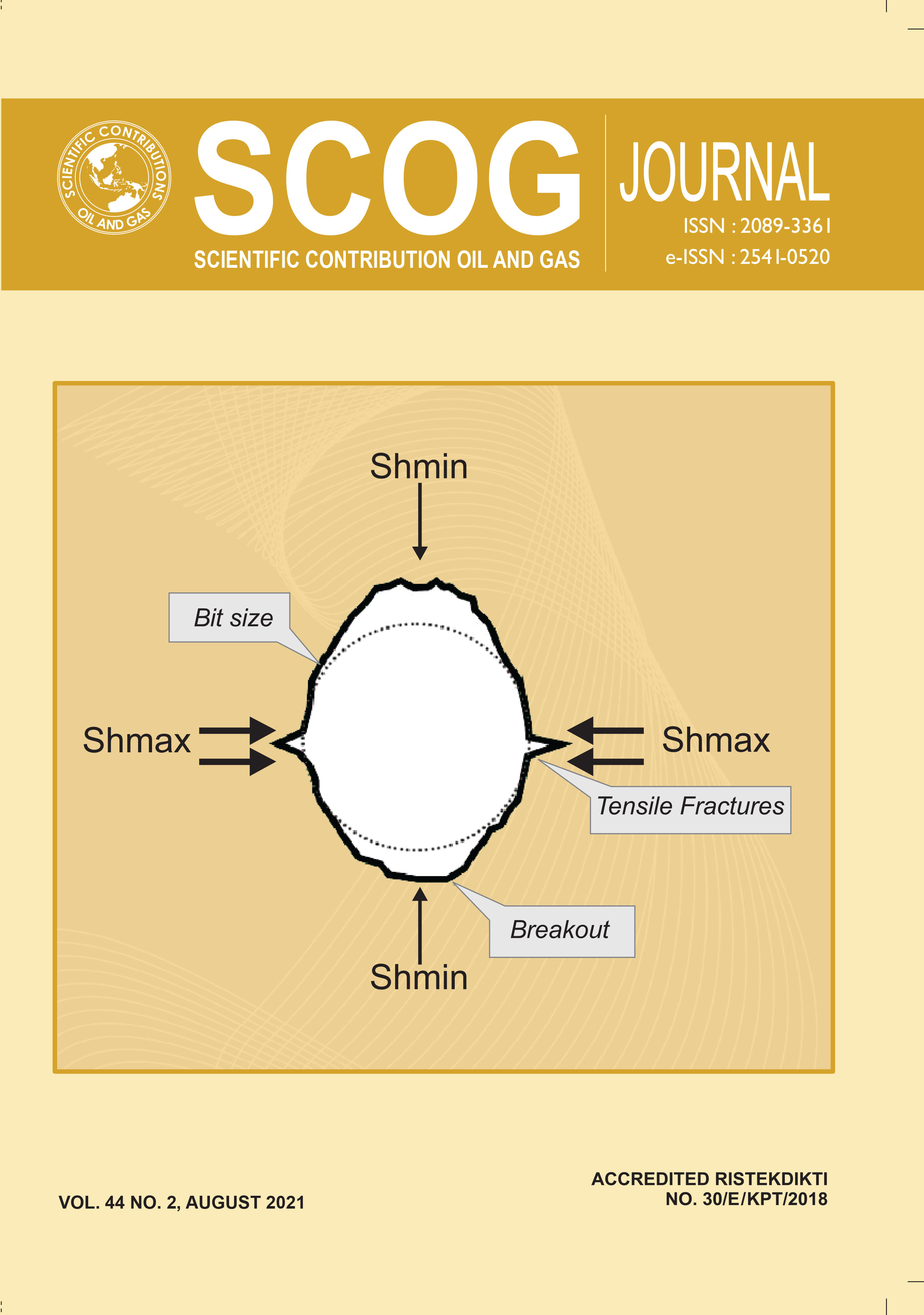

Shale is one of the rocks that often causes drilling problems because shale tends to swell or swell when in contact with mud filtrate, mainly Water-base Mud (WBM). This study aims to determine how the performance of Oil-base Mud (OBM) based on Crude Coconut Oil (CCO) in overcoming the swelling problem. The methodology used consists of drilling simulation and cutting analysis in the X-Ray Diffraction (XRD) laboratory. The series of activities in the study began with the preparation of rock layers, followed by testing the penetration rate using Water-base Mud as a comparison. After cutting analysis was carried out in the XRD laboratory of UPN “Veteran†Yogyakarta with the Rigaku tool, then replaced the type of drilling fluid Oil-base Mud with basic materials alternative to Crude Coconut Oil (CCO) and followed by a penetration test. Rate of Penetration (ROP) test results from WBM with Rheology 1 at interval A or a depth of 1.96 ft-4.92 ft is 442.8 ft/h, Rheology 2 at interval B or a depth of 4.92-10.5 ft is 118.5 ft/hr on the first day. Swelling occurred and results in pipe sticking at depth of 6.5 ft. Based on the Bulk Mineral analysis, clay mineral content is 23.84%. Based on the Clay Oriented, smectite dominates the clay by 29.09%. Based on MBT, shale belongs to class B (illite and mixed-layer montmorillonite illite), where this mineral can expand. Based on a Geonor As test, 5.18% of the cutting can develop when exposed to water. The drilling fluid was replaced with Oil-base Mud based on alternative Crude Coconut Oil (CCO), and obtained ROP Rheology 1 at Interval A of 492 ft/h and Rheology 2 at Interval B of 480 ft/h. The results of the Compressive Strength test interval A on the first, third, and fifth days were 31,699 psi, 42,265 psi, and 52,831 psi. The results of the Compressive Strength test interval B on the first, second, and third days were 31,496 psi, 41,517 psi, and 52,971 psi. Based on clay mineral analysis and magnitude of ROP value, is known that Crude Coconut Oil (CCO) based Oil-base Mud is effective because during the simulation, there are no drilling problems, and the resulting ROP value is greater than the first day Water-base Mud.References

Adams, N J., “Drilling Engineering,†A Complete Well Planning Approach Penn Well Publishing Co, Tulsa Oklahoma, 1985.

American Petroleum Institute, “Specification for Drilling Fluids Specifications and Testing,†Dallas, 2010.

Baroid Fluid Services Fluids Handbook, Halliburton Fluid Systems, 2006.

Bourgoyne, A. T., Millheim, K. K., Chenevert, M. E., & Young, F. S. (1991). Applied Drilling Engineering. United States of America: Society Of Petroleum Engineers.

Davarpanah, A., Zarel, M., & Nasabeh SM, M, “Assessment of Mechanical Specific Energy Aimed at Improving Drilling Inefficiencies and Minimize Wellbore Instability,†Journal of Petroleum & Environmental Biotechnology 2, 2016.

Herianto, & Askeyanto, D., “Analisa Swelling Clay Formasi Telisa Untuk Perencanaan Lumpur Pemboran. Seminar Nasional Kebumian X - FTM - UPN “Veteran†Yogyakarta (p. 224),†Yogyakarta, FTM UPN “Veteran†Yogyakarta, 2015.

Pitre, Brandon Thomas, “Application of the modified Methylene Blue Test to detect clay minerals in coarse aggregate fines,†Texas A&M University, 2012.

Suhascaryo, Nur, “The Effects of VICOIL Bopanprog Usage as a Substitute for Crude Oil for Oil-Based Drilling Fluids,†Proceeding on Engineering and Science Series (ESS), vol. 1, no. 1, 2020.

Suhascaryo, Nur., & Yudiantoro, A. (2020). Proses Aktivasi Dalam Peningkatan Kualitas VICOIL BOPANPROG Desa Bojong, Kecamatan Panjatan, Kabupaten Kulonprogo. Yogyakarta: Uwais Inspirasi Indonesia.

Wicaksono, D. D., Setiawan, N. I., Wilopo, W., & Harijoko, A., “Teknik Preparasi Sampel Dalam Analisis Mineralogi Dengan XRD (X-Ray Diffraction) -Di Departemen Teknik Geologi, Fakultas Teknik, Universitas Gadjah Mada,†Seminar Nasional Kebumian Ke-10 (pp. 1864-1880). Yogyakarta: Universitas Gadjah Mada. 2017.

Downloads

Published

Issue

Section

License

Copyright (c) 2021 © Copyright by Authors. Published by LEMIGAS

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors are free to Share — copy and redistribute the material in any medium or format for any purpose, even commercially Adapt — remix, transform, and build upon the material for any purpose, even commercially.

The licensor cannot revoke these freedoms as long as you follow the license terms, under the following terms Attribution — You must give appropriate credit , provide a link to the license, and indicate if changes were made . You may do so in any reasonable manner, but not in any way that suggests the licensor endorses you or your use.

No additional restrictions — You may not apply legal terms or technological measures that legally restrict others from doing anything the license permits.